The British Fluid Power Distributors Association (BFPDA) has launched a campaign to warn against the dangers of re-ending hydraulic hoses – all too prevalent in the construction industry, it seems.

“The pandemic has us all under extra strain and I know that many company owners or workers across the construction industry will be looking for ways to save money – but let me tell you now, re-ending hoses to save a few pounds is not the answer,” said BFPDA chairman Nigel Thomason.

“That’s why we’ve launched our latest campaign. We want to make sure that when you have a hose replaced, it’s done by one of our quality approved suppliers who categorically will refuse to re-end hose.”

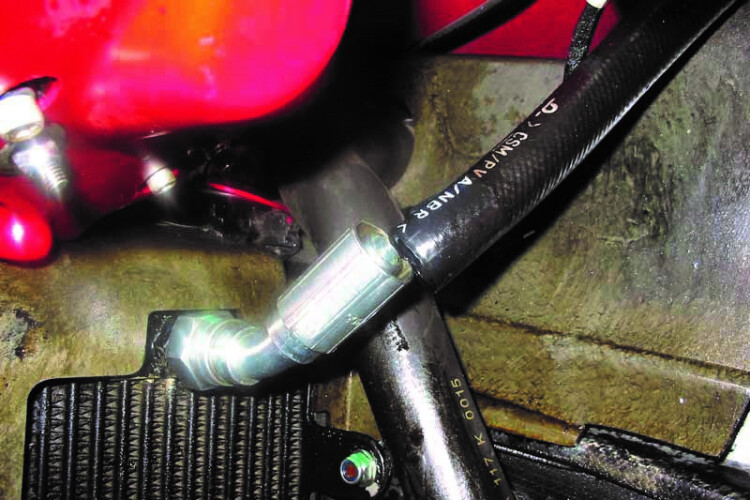

Hydraulic hoses are found on almost every construction vehicle such as excavators and dumper trucks as well as many power tools and lifting devices, and are subject to all types of wear and tear. A pinhole leak in a hose can eject fluid at near-bullet speeds of more than 180 metres per second, depending on the pressure that it is under.

In Nigel Thomason’s experience few construction workers understand the dangers of pressure systems. It is quite normal for fluid to be under pressure at 2000 PSI (168 Bar) in a hydraulic hose on a construction vehicle, and can be as much as 6000 PSI (414 Bar), he says. A pressure of just 100 PSI (or 6.9 Bar) is enough to puncture the skin.

Oil under this pressure can lead to severe, even fatal, injuries from just one tiny looking pin prick.

And this type of injury can be directly caused by hose re-ending, he says, because it fundamentally changes the structural make-up of the hose, leading to damage and deterioration.

“Re-ending hoses is a dangerous practice which can lead to fatal injuries – ultimately you’re chancing with a liquid bullet,” Mr Thomason continues. “Cost is the biggest driver in re-ending but it’s the integrity of the whole assembly that’s ruined when you do that, not just the end of a hose. Re-ending increases the risk of failure and is never covered by the hose manufacturer’s warranty, so it really is a false economy.”

The British Fluid Power Association operates an approved hose assemblies scheme, with a Q ‘quality’ logo denoting certification.

See hydraulichosesafety.co.uk for details

Got a story? Email news@theconstructionindex.co.uk