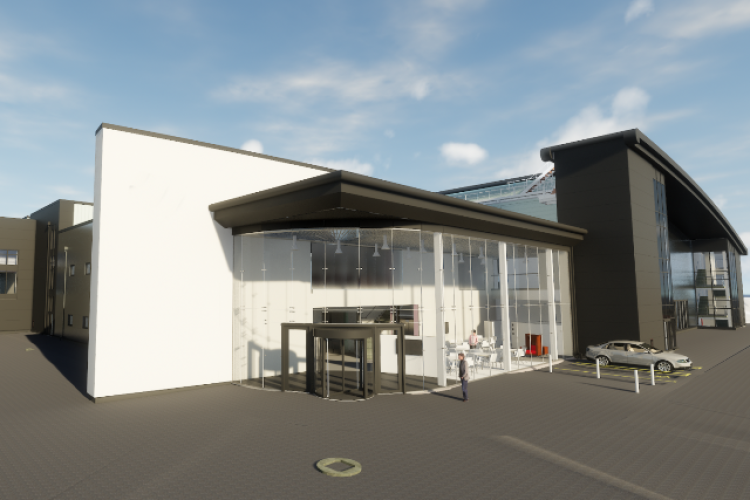

GSK has been in Barnard Castle since the 1940s. Its latest investment in facilities is an 11,500 m2 Q Block aseptic facility that will allow it widen its range of products for HIV, respiratory and oncology treatments.

GSK opted to maximise offsite construction as a way of controlling quality and the build programme. It also wanted a building that could be replicated anywhere in the world to standardise procedures and minimise repeat design costs.

SES says that it got the fit-out job in part because of its ability to meet the offsite construction requirements.

Now on site, SES will work to a detailed schedule of works to install all mechanical and electrical (M&E) building services, ensuring that there is minimum disruption to the live manufacturing site. GSK expects Q Block to be completed by November 2019.

Not only are the M&E services benefiting from offsite technology, 40% of the building’s shell is being created offsite, including precast units, wall systems, steel framework and 95% of a 2,500 m2 clean room.

Steve Joyce, SES’ business director for Scotland and the north of England, said: “GSK is a forward-thinking company which identified and appreciated the importance of getting SES onboard at the earliest opportunity. This early engagement coupled with our BIM Level 2 experience and bespoke offsite capability, via our offsite manufacturing facility, Prism, allowed us to influence the M&E design at the outset of the project.

“As a result, a significant 60% of the MEP [mechanical, electrical, plumbing] services will be produced offsite which meets a key target of GSK’s brief to replicate the building elsewhere in the world.

“I believe Q Block is an excellent example of offsite construction being used to best effect and I am delighted that SES has made such a positive contribution to the scheme.“

GSK project manager Colin Driver added: “This is an exciting phase in the ongoing development of our Barnard Castle manufacturing facility. The investment in biopharmaceuticals is critical to the future of pharmaceuticals and this is a flagship project for global investment.

“The idea is to replicate the design globally on secondary sites, building in the flexibility within individual modules, but also future-proofing the design for at least 10-20 years without the risk of drug regulatory impact, hence reducing future design costs. I believe this can only be achieved using offsite technology.”

Got a story? Email news@theconstructionindex.co.uk